Improving indoor air quality

In our quest for excellence improving indoor air quality (IAQ), we understand that ensuring the health, comfort, and satisfaction of building occupants is of utmost importance. This comprehensive guide will walk you through the critical aspects of maintaining superior air quality in your building, exceeding the standards set by the Environmental Protection Agency (EPA).

Indoor Air Quality, or IAQ, refers to the condition of the air within and around buildings and structures, especially as it relates to the health and comfort of occupants. Maintaining excellent IAQ is vital as it can significantly impact the well-being and productivity of those within the space.

Ensuring exceptional IAQ promotes better health for occupants.

Poor air quality can lead to respiratory problems, allergies, and other health issues. In contrast, optimal IAQ reduces the risk of such ailments, creating a healthier environment for everyone.

Superior IAQ contributes to the comfort of building occupants.

Proper temperature, humidity levels, and the absence of pollutants create a more pleasant and inviting atmosphere, boosting overall satisfaction.

Poor air quality has been linked to

- sick building syndrome

- reduced productivity

- negative customer experience

Common pollutants of indoor air include:

- Pollutants from indoor combustion

- Pollutants from indoor combustion

- radon

- molds and other allergens

- carbon monoxide

- airborne hydrocarbons

- volatile organic compounds

- legionella and other bacteria

- legionella and other bacteria

Source control, filtration, and the use of ventilation to dilute contaminants are the primary methods for improving indoor air quality in most buildings.

But in most circumstances they are only recirculating the air, not purifying it.

Proper ventilation is paramount to maintaining superior IAQ. It ensures the circulation of fresh outdoor air and the removal of indoor air pollutants. Regularly maintain and inspect your building's ventilation systems to guarantee they are functioning optimally.

Microbial activity circulates throughout your building and thrives on all surfaces.

A well-ventilated and pollutant-free environment can lead to increased productivity. Employees and residents in a building with superior IAQ tend to perform better and are less likely to experience fatigue or discomfort.

Proper ventilation is paramount to maintaining superior IAQ. It ensures the circulation of fresh outdoor air and the removal of indoor air pollutants. Regularly maintain and inspect your building's ventilation systems to guarantee they are functioning optimally.

Routine maintenance of HVAC systems, air filters, and building infrastructure is crucial for sustaining exceptional IAQ.

Create a maintenance schedule and stick to it diligently.

Welcome to a comprehensive guide on improving indoor air quality. In this article, we'll explore the importance of breathing clean air indoors and provide practical tips to achieve just that. Are you ready to discover the secrets to a healthier home environment? Let's get started!

- Understanding Indoor Air Quality

- Common Indoor Air Pollutants

- The Health Impacts

- Ventilation Matters

- Humidity Control

- Choosing the Right Air Purifier

- Houseplants: Natural Air Purifiers

- Cleanliness is Key

- Allergies and Indoor Air Quality

- DIY Air Quality Testing

- Conclusion: Breathe Easier at Home

- FAQs About Indoor Air Quality

Let's start by demystifying indoor air quality (IAQ). IAQ refers to the quality of the air within buildings, including homes, offices, and schools. It's all about the air you breathe while indoors.

Indoor air can harbor various pollutants, including dust, pet dander, pollen, and even volatile organic compounds (VOCs) from cleaning products.

Poor IAQ can lead to a range of health issues, from allergies and respiratory problems to headaches and fatigue. It's essential to recognize these symptoms and address the root cause.

Proper ventilation is key to maintaining good IAQ. Ensure your home has adequate ventilation to allow the exchange of indoor and outdoor air.

Maintaining the right humidity level in your home is crucial. Too much moisture can lead to mold growth, while excessive dryness can cause respiratory discomfort.

Investing in an air purifier can significantly improve IAQ. Look for one that suits your needs and room size. HEPA filters are excellent for trapping particles.

Plants aren't just for decoration; they can also help purify the air. Consider adding some indoor plants like snake plants or peace lilies to your space.

Regular cleaning and dusting can go a long way in reducing indoor air pollutants. Don't forget to vacuum carpets and upholstery too!

Allergies are often aggravated by poor IAQ. Learn how to create an allergen-free environment for yourself and your family.

Want to know exactly what's in your indoor air? DIY air quality testing kits are readily available and can provide valuable insights.

In conclusion, your indoor air quality matters more than you might think. By following the tips and strategies outlined in this article, you can significantly enhance the air you breathe within your home. Remember, a healthier indoor environment leads to a healthier you!

Common signs include frequent allergies, coughing, sneezing, headaches, and a general feeling of discomfort while indoors.

You can improve IAQ by maintaining proper ventilation, keeping your home clean, reducing humidity, and adding air-purifying houseplants.

Yes, scented candles can release VOCs and other pollutants into the air. Opt for natural, unscented candles or consider using an essential oil diffuser.

Yes, it can. Poor IAQ can lead to breathing difficulties and discomfort, which may disrupt your sleep patterns.

It's advisable to check the manufacturer's recommendations, but generally, filters should be changed every 3 to 6 months for optimal performance.

Now that you're armed with knowledge on how to improve your indoor air quality, take action and create a healthier living space for yourself and your loved ones. Breathe easy and enjoy the benefits of clean, fresh air indoors.

Improving indoor air quality hvac

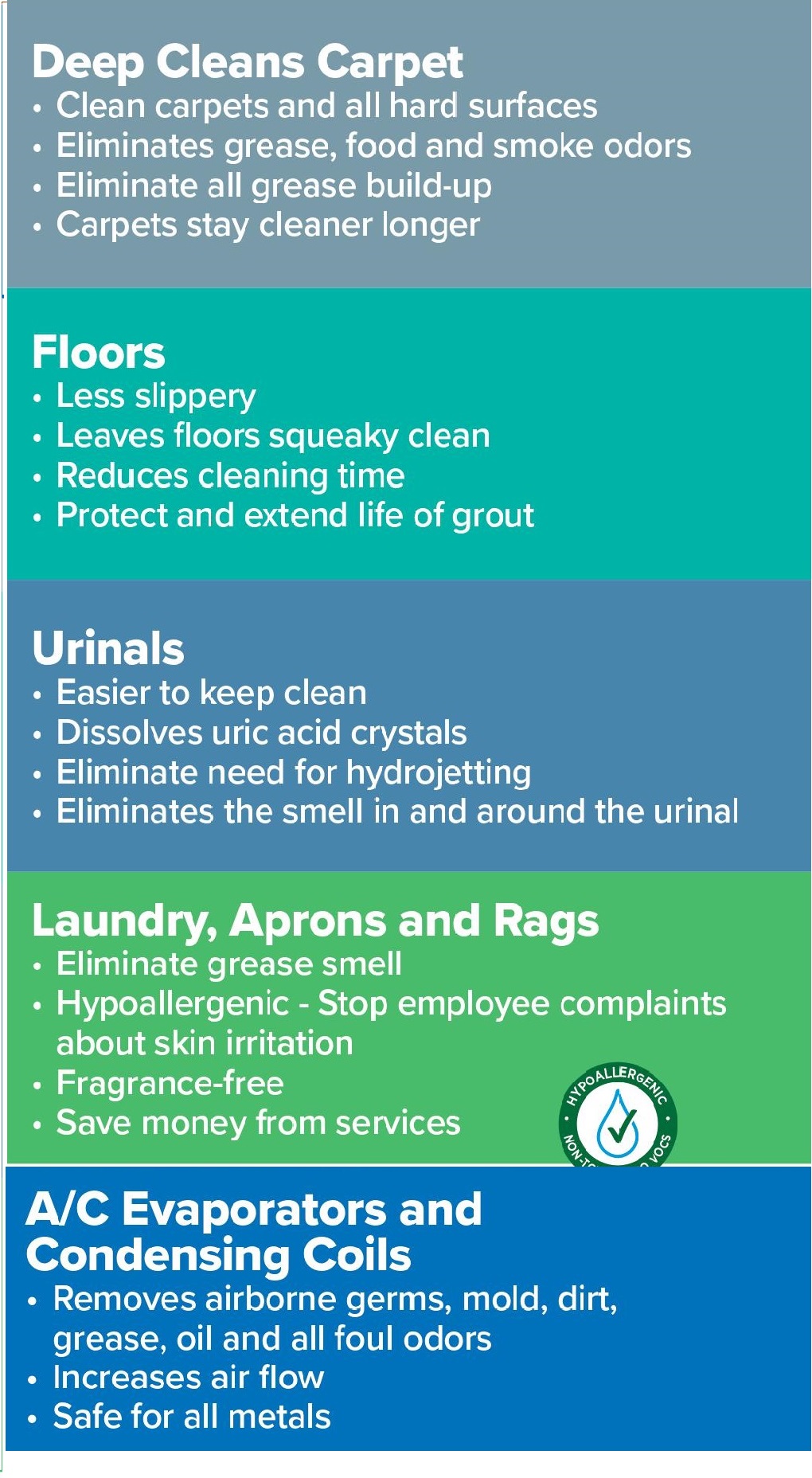

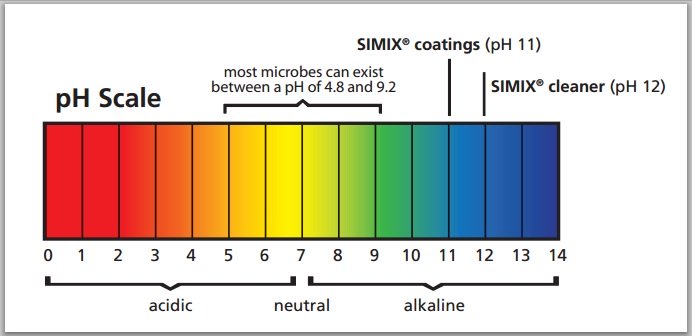

Simix HVAC coating with photocatalytic titanium dioxide can play a significant role in improving indoor air quality in various ways:

- Mold and Mildew Prevention: Mold and mildew growth within HVAC systems can negatively impact indoor air quality. Simix HVAC coating helps in preventing the growth of mold and mildew by inhibiting their development on coated surfaces. This not only maintains cleaner air ducts but also reduces the chances of these harmful microorganisms being circulated into the indoor air.

- Airborne Contaminant Reduction: Simix HVAC coating contains photocatalytic titanium dioxide, which is a powerful catalyst when exposed to light. When applied to HVAC system components such as ducts, coils, and filters, it can actively break down and neutralize various airborne contaminants. This includes volatile organic compounds (VOCs), bacteria, viruses, mold spores, and even odorous substances. As these contaminants come into contact with the coated surfaces and are exposed to light, they undergo a chemical reaction that reduces their concentration in the indoor air.

Buy Simix Here

Mention (SAVETH ) for discount

Mold and Mildew Prevention

- Mold and mildew growth within HVAC systems can negatively impact indoor air quality. Simix HVAC coating helps in preventing the growth of mold and mildew by inhibiting their development on coated surfaces. This not only maintains cleaner air ducts but also reduces the chances of these harmful microorganisms being circulated into the indoor air.

- Reduction of Odors: Simix HVAC coating can effectively reduce odors by breaking down odor-causing molecules. This is particularly beneficial in environments where odors from cooking, pets, or other sources can be a concern.

- Rather than masking odors with fragrances, the coating addresses the root cause by eliminating the odor molecules themselves.

- Improved Energy Efficiency:

- Cleaner HVAC system components, such as coils and ducts, can operate more efficiently. This means that the HVAC system consumes less energy to achieve the desired temperature and air quality. Improved efficiency not only reduces energy costs but also contributes to a more sustainable and eco-friendly operation.

- Enhanced Air Quality: By actively addressing contaminants and promoting cleaner HVAC systems, Simix HVAC coating contributes to a healthier indoor environment. Reduced airborne allergens, pollutants, and pathogens can lead to improved respiratory health and overall well-being for building occupants.

- Long-Term Durability: Simix HVAC coating offers long-lasting protection. Once applied, it continues to work over an extended period, providing ongoing benefits for indoor air quality without the need for frequent reapplications.

In summary, Simix HVAC coating with photocatalytic titanium dioxide is a proactive and sustainable solution for improving indoor air quality. It works by actively breaking down and neutralizing contaminants, preventing mold and mildew growth, reducing odors, improving energy efficiency, and promoting a healthier and more comfortable indoor environment for building occupants.

- Air purification

- Clean indoor air

- Indoor environment

- Healthy home air

- Air quality control

- Indoor pollution

- HVAC filtration

- Indoor allergens

- Ventilation systems

- IAQ monitoring

- Mold prevention

- Pollutant removal

- Indoor climate

- Indoor air contaminants

- Dust filtration

- Respiratory health

- Home air quality

- Allergen control

- IAQ solutions

- Fresh indoor air

- Airborne particles

- Indoor ventilation

- Indoor air testing

- IAQ maintenance

- Indoor air standards